The transformation of raw ingredients into consumable products is the core of food processing.

It can be as basic as freezing or canning. The industry plays a key role in our daily lives, ensuring food is safely transported from farm to table.

However, this process involves several steps, including harvesting, cleaning, packaging, and transport, all designed to deliver food safely to consumers.

As processed foods come under increasing scrutiny, the industry is responding to environmental and sustainability concerns.

To address these challenges, it is adopting eco-friendly packaging, innovations in food manufacturing, and energy-efficient processing methods.

In this post, we will explore everything you need to know about food processing, including an industry overview, emerging trends and innovations, different types of processing techniques, the shift toward sustainable practices, and the role of regulatory agencies in maintaining food safety.

What is Food Processing?

Food processing refers to the methods used to transform raw ingredients into safe, edible food products.

The process involves a range of physical, chemical, and biological techniques designed to change raw materials’ form, texture, or composition to achieve this transformation.

Common examples include milling grains into flour, pasteurizing milk, fermenting yogurt, and canning vegetables.

These processes make food more palatable and convenient, enhance its safety by eliminating harmful pathogens, and extend shelf life.

Moreover, by controlling the environment in which food is processed, food manufacturers can ensure that the final products meet quality and safety standards, making them suitable for consumption and distribution.

Here’s a quick list of processed food consumed by the people worldwide:

- Processed meat

- Dairy products

- Edible oils

- Processed fruit and vegetables

- Baked goods

- Snack foods

- Pet foods

The Food Processing Industry: A Global Overview

The food processing market is projected to grow from $163.79 billion in 2024 to $400.43 billion by 2030, exhibiting an annual growth rate (CAGR) of 11.82% during the forecast period (2024 – 2030).

Food processing has seen significant advancements. The industry is expanding to meet growing health concerns, food demands, and environmental needs.

For example, new food technologies are being developed to reduce and reuse food waste, which is important as the global population approaches 9 billion by 2050.

The global food processing industry is driven by several leading companies that dominate the market. Here’s a look at some of the major players:

- Buhler: A Swiss multinational known for advanced food processing equipment and solutions.

- Krones AG: A German company specializing in bottling and packaging technology.

- AFE Group Ltd.: Based in the UK, AFE Group Ltd. provides key food service equipment.

- Atlas Pacific Engineering Company Inc.: An American company recognized for expertise in fruit and vegetable processing machinery.

- B.K Engineers: An Indian company focused on food processing and packaging machinery.

- National Refractories: Known for industrial thermal products, supporting food processing needs.

- Heat and Control, Inc.: A U.S.-based company offering a broad processing and packaging equipment range.

- Meyer Industries: Significant in the field of food handling and processing equipment.

- ZIEMANN HOLVRIEKA: A German leader in brewing and beverage processing systems.

- Tomra Systems: A Norwegian company that is leading in sensor-based sorting and processing technology.

Trends and Innovations

The food processing industry is continuously evolving, driven by emerging trends and innovations that address consumer demands, environmental concerns, and technological advancements.

Sustainable Processing

Sustainability has become a major focus in food processing, with companies adopting practices that reduce environmental impact.

Firstly, processes are optimized to minimize food waste with technologies that enhance sorting, packaging, and production efficiency. Additionally, advances in processing equipment are leading to lower energy consumption and reduced carbon footprints.

For example, energy-efficient ovens and refrigeration systems are becoming standard. Moreover, there is a growing shift towards biodegradable and recyclable packaging materials to reduce plastic waste and environmental pollution.

Food Technology

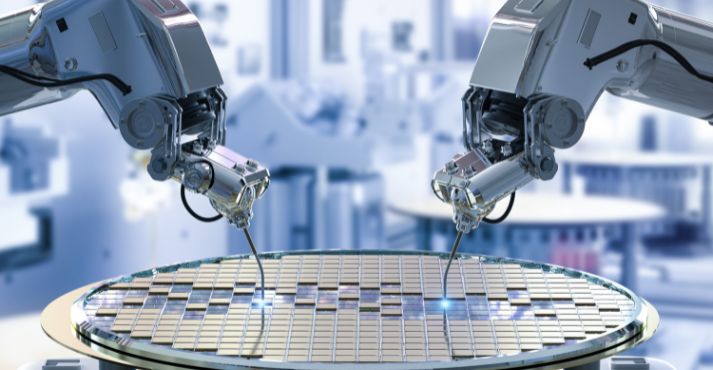

Automation and artificial intelligence are streamlining food production, improving accuracy and efficiency. Robotics are now employed for sorting, packaging, and quality control tasks.

In addition, precision fermentation technology allows for the production of specific ingredients and flavors by manipulating microorganisms, which reduces the need for traditional fermentation processes.

Moreover, research into lab-grown meat and alternative protein sources provides consumers with sustainable and ethical options while reducing reliance on traditional animal farming.

Health and Wellness

Health-conscious consumers are driving the demand for processed foods that offer nutritional benefits. In response to this trend, functional foods are becoming increasingly popular, featuring enhancements like probiotics, vitamins, and minerals that promote health and well-being.

Also, there is a growing emphasis on clean labeling, which focuses on transparency in ingredients and processing methods and highlights natural and minimally processed products.

Digital Transformation

Digital tools transform the food processing industry, enabling better data management and decision-making. Firstly, IoT (Internet of Things) technology uses connected devices to monitor processing conditions, improving consistency and quality.

Additionally, blockchain technology is utilized for traceability and transparency in the supply chain, enhancing food safety and authenticity.

Types of Food Processing

Food processing can be done through different methods and steps. Each type plays a distinct role in preparing food for consumption and enhancing its safety, shelf life, and convenience.

1. Primary Processing

Primary processing refers to the initial steps to prepare raw food materials after they are harvested or collected. These basic preparation steps make raw ingredients safe for consumption and further processing.

Here are the steps involved in primary food processing:

- Washing: Removes dirt, pesticides, and other contaminants from raw food items.

- Peeling: Removes the outer skin or shell, which may be inedible or contain harmful substances.

- Cutting: Involves chopping, slicing, or dicing raw food into manageable pieces for cooking or packaging.

- Blanching: Briefly boiling food, such as vegetables, to kill surface bacteria and deactivate enzymes that cause spoilage.

Lastly, primary processing ensures that raw foods are clean, safe, and ready for direct consumption or further processing. This stage is often carried out immediately after harvesting to maintain the freshness and quality of the produce.

2. Secondary Processing

Secondary processing involves transforming raw ingredients into more complex food products. This stage goes beyond basic preparation, involving various techniques to create foods that are more refined, flavorful, and ready for packaging or cooking.

Here are some common examples of secondary processing:

- Baking: Mixing and heating ingredients to create bread, cakes, or pastries.

- Fermenting: Using bacteria or yeast to convert sugars into alcohol or acids, producing foods like cheese, yogurt, and beer.

- Canning: Seal food in airtight containers and heat it to sterilize, allowing for long-term storage.

- Pasteurization: Heating liquids, such as milk or juice, to kill harmful bacteria and extend shelf life.

Secondary processing adds value to raw ingredients by turning them into finished products that are easier to consume, store, and transport. Food manufacturers often employ these techniques to produce a wide range of everyday food items.

3. Tertiary Processing

Tertiary processing focuses on the creation of ready-to-eat or convenience foods. These products require minimal consumer preparation, making them ideal for busy lifestyles.

Also, it often involves combining multiple ingredients, adding preservatives, and packaging the final product.

Here are some common examples of tertiary processing:

- Freezing: Producing frozen meals that only need reheating before consumption.

- Snack Foods: Manufacturing chips, cookies, or candies pre-cooked and packaged for immediate consumption.

- Meal Kits: Assembling pre-portioned ingredients with minimal preparation steps required at home.

Tertiary processing caters to the growing demand for convenience, offering consumers quick and easy meal options with minimal effort.

The Role of Food Processing in Food Safety

Food processing transforms raw ingredients into safe and edible products, enhancing shelf life and quality and helping eliminate potential hazards.

One primary way food processing contributes to food safety is by eliminating harmful pathogens and contaminants.

For example, meat, poultry, and vegetables can transfer bacteria, viruses, parasites, and chemical contaminants that pose significant health risks.

As a result, food processing techniques such as pasteurization, sterilization, irradiation, and high-pressure processing are designed to destroy these pathogens and reduce the risk of foodborne illnesses.

Here’s how preservation in food processing techniques can prevent food spoilage:

1. Freezing

Freezing food slows the growth of bacteria, yeast, and molds that cause spoilage. By lowering the temperature to below freezing, the activity of these microorganisms is halted.

2. Drying

Without sufficient water, bacteria and fungi cannot grow; therefore, drying will extend the shelf life of foods like fruits, vegetables, and meats.

3. Canning

Canning involves sealing food in airtight containers and heating them to destroy any microorganisms. The absence of air and heat application prevents spoilage, allowing canned foods to remain safe and edible for years.

4. Vacuum Sealing

Vacuum sealing removes air from packaging, reducing the oxygen available for microbial growth. Moreover, it also slows down the spoilage process by limiting the conditions needed for bacteria and molds to multiply.

5. Pickling

The high acidity or salt content inhibits the growth of spoilage-causing bacteria, keeping the food safe for longer. Therefore, pickling preserves food by immersing it in a vinegar or brine solution.

6. Pasteurization

Pasteurization involves heating food to a specific temperature to kill harmful bacteria and enzymes that can cause spoilage. The most common use cases are milk, juice, and other perishable liquids.

7. Fermentation

Fermentation is a natural preservation method that enhances the flavor of foods like yogurt, sauerkraut, and kimchi but also creates an acidic or alcoholic environment that inhibits spoilage.

Food Processing Regulations and Standards

According to recent data from the Centers for Disease Control and Prevention published by the FDA, about 48 million people in the U.S. (1 in 6) get sick, 128,000 are hospitalized, and 3,000 die each year from foodborne diseases.

Given these alarming statistics, food safety is ensured by adhering to food processing regulations and standards.

To achieve this level of safety, government agencies and international bodies establish these regulations to ensure that food products are processed under safe and hygienic conditions, minimizing the risk of contamination.

At every stage of production, food processors must comply with these regulations, from sourcing raw materials to packaging the final product.

In the United States, the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) set food safety standards that processors must follow.

Among these standards, Hazard Analysis Critical Control Points (HACCP) guidelines require food processors to identify and control potential hazards in the production process.

Also, the Singapore Food Agency (SFA) oversees the regulatory functions of the Agri-Food and Veterinary Authority of Singapore (AVA), the National Environment Agency (NEA), and the Health Sciences Authority (HSA), streamlining food-related regulations under one umbrella organization.

Additionally, the Global Food Safety Initiative (GFSI) benchmarks food safety standards worldwide, promoting consistency and transparency in food safety practices across countries.

Future Trends in Food Processing: Embracing the Clean Label Movement

Clean Label Movement: Meeting the Demand for Minimally Processed Foods

As we look ahead to the future of food processing, one notable trend is the clean label movement. Let’s dig into what this movement entails and how it’s shaping consumer preferences for minimally processed foods:

Clean Label Movement

The clean label movement shifts consumer preferences towards foods with simple and natural ingredients. It’s about transparency, with consumers seeking clear and straightforward information about what goes into their food.

Minimally Processed Foods

This movement is impacting the demand for minimally processed foods. Consumers are increasingly drawn to products that undergo minimal processing, emphasizing the goodness of natural ingredients without unnecessary additives.

Understanding the clean label movement and its influence on the demand for minimally processed foods is like peering into the future of our plates.

It reflects a growing awareness and preference for food that is convenient and aligns with our desire for simplicity and transparency in what we eat.

Technological Innovations: Paving the Way in Food Processing

Looking into the future of food processing unveils a landscape of exciting technological innovations. Let’s explore the impact of emerging technologies, including automation, AI, and intelligent food packaging:

Automation in Food Processing

Automation is transforming the way we process food. From precision in manufacturing to streamlining repetitive tasks, automation enhances efficiency in the entire food processing chain.

AI in Food Manufacturing

Artificial Intelligence (AI) is not just a concept from sci-fi; it’s making its mark in food processing. AI applications are optimizing production processes, ensuring quality, and even contributing to recipe creation.

Smart Packaging

The packaging itself is getting smart. Innovations in intelligent packaging include features like freshness indicators and temperature monitoring, ensuring that the food you get is conveniently stored and delivered precisely.

Understanding these technological advancements in food processing is like glimpsing into a future where efficiency, quality, and convenience come together seamlessly.

It’s about embracing innovation to ensure the food we enjoy is delicious and a product of cutting-edge technologies.

Conclusion

The food processing industry is rapidly evolving with trends enhancing sustainability, technology, and health benefits.

The key players in the industry are embracing practices that reduce environmental impact, such as waste reduction, energy efficiency, and eco-friendly packaging.

Meanwhile, innovations like automation, precision fermentation, and lab-grown foods are revolutionizing production methods and product offerings.

Additionally, health-conscious consumers fuel demand for functional foods and clean labeling, ensuring transparency and nutritional value.

Despite any challenges food processors may face, businesses continue to move forward with a shift towards more sustainable technologies and environmentally friendly innovations.

The food processing industry offers significant opportunities for businesses that can adapt to changing trends and consumer preferences.