When we eat at a restaurant or buy packaged food from the store, we trust that it’s safe to consume. But have you ever wondered what goes on behind the scenes to ensure food safety? What is HACCP, and how does it help?

HACCP, or Hazard Analysis and Critical Control Point, is a food safety management system that aims to prevent hazards before they occur in food production.

It was first developed in the 1960s for NASA’s space missions, where food safety was essential to protect astronauts’ health.

Today, HACCP is widely used across the food industry, from restaurants to manufacturing plants. It’s essential for restaurant owners, food manufacturers, and food safety specialists.

When following HACCP, these professionals ensure that every step of the food process meets strict safety standards, helping to prevent contamination and reduce risks.

Adopting HACCP doesn’t just protect consumers; it also supports food regulatory compliance and builds consumer trust.

What is HACCP?

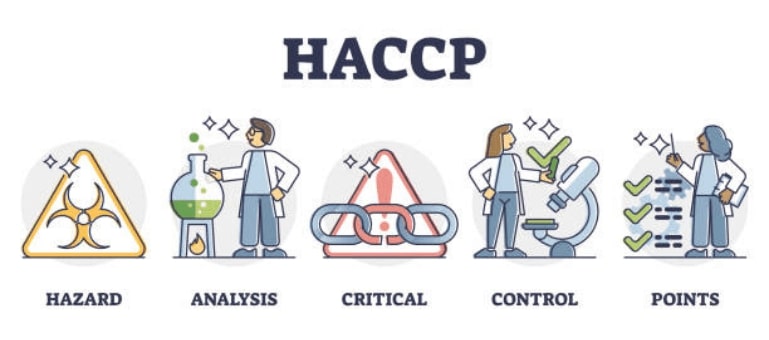

HACCP stands for Hazard Analysis and Critical Control Point, a system designed to prevent foodborne risks by identifying and controlling potential hazards throughout food production.

Foodborne illness can result from contamination during food handling, so HACCP provides a structured approach to control these risks and keep food safe.

Breaking down the acronym:

- Hazard Analysis: This is the process of identifying potential hazards in food production, such as biological (bacteria or viruses), chemical (pesticides or allergens), or physical (metal fragments) risks that could harm consumers.

- Critical Control Points (CCP) are specific points in food production where hazards can be prevented, reduced, or eliminated.

HACCP helps businesses understand where dangers exist in their operations and how to manage them effectively.

Following HACCP allows food businesses to take a proactive approach to food safety. This approach not only reduces contamination risks but also aligns with industry standards and food regulatory compliance requirements, as seen in Singapore’s SFA food regulation.

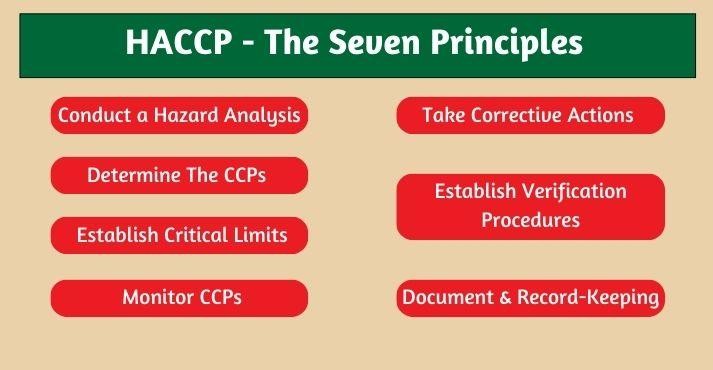

The Seven Principles of HACCP

The HACCP system is based on seven essential principles, which act as guidelines for creating and implementing effective food safety measures.

1. Conduct a Hazard Analysis

The first step in HACCP is conducting a hazard analysis to identify possible hazards at each stage of food production. Food safety can potentially be compromised by biological hazards (like bacteria), chemical (like cleaning agents), or physical (like broken glass).

During the analysis, food safety professionals closely examine each step in food processing, from receiving raw materials to cooking and packaging, to pinpoint areas where contamination could occur.

For instance, a food manufacturer might examine its supply chain to assess if any suppliers present a contamination risk. This step ensures that potential dangers are known and can be managed before they become a problem.

Recognizing and comprehending these hazards is essential for any business aiming to meet food regulatory compliance standards and protect consumers.

2. Determine Critical Control Points (CCPs)

Once potential hazards are identified, the next step is to identify Critical Control Points (CCPs). These are stages in the production process where hazards can be controlled or eliminated.

When focusing on specific control points, businesses can target the most critical areas for maintaining food safety.

For example, cooking is a critical control point in food production because high temperatures kill harmful bacteria, reducing the risk of foodborne illness.

Each CCP represents a point where monitoring is essential to ensure food safety. Identifying these points is key to effective HACCP implementation, helping businesses prevent contamination and comply with regulations, as emphasized in Singapore’s approach to food regulatory compliance.

3. Establish Critical Limits

After pinpointing the CCPs, it’s crucial to set critical limits for each. A critical limit is a specific value—like a temperature or time—that must be met at each CCP to ensure food safety. If the process doesn’t meet this limit, the food could be unsafe to consume.

For instance, a critical limit for chicken might require cooking it to an internal temperature of 75 degrees Celsius (167 degrees Fahrenheit) to ensure all bacteria are killed.

When setting clear limits, HACCP helps businesses control each step of the food production process, ensuring it aligns with safety standards.

4. Monitor CCPs

Monitoring CCPs is vital to maintaining food safety. Monitoring involves checking each critical control point to ensure it meets the established limits. Regular monitoring allows businesses to keep track of the food production process and catch any problems early.

For example, a food processing facility might check the temperature of cooked foods at regular intervals to ensure they meet safety requirements.

If a deviation occurs, it can be quickly corrected to prevent contaminated food from reaching consumers. Monitoring is crucial for food regulatory compliance, demonstrating that businesses are actively working to control food safety risks.

5. Take Corrective Actions

If a CCP does not meet its critical limit, corrective actions are necessary to bring it back under control. Corrective actions are predetermined steps taken when a CCP is out of range, helping prevent contamination and protect consumers from potential hazards.

For instance, if a temperature check shows that cooked meat didn’t reach the critical limit, the corrective action might involve reheating or discarding the product. When having corrective actions in place, businesses can manage risks effectively, ensuring that food safety is maintained.

6. Establish Verification Procedures

Verification procedures are essential to confirm that the HACCP system functions as intended. Verification can involve checking records, testing products, or conducting audits. Regular verification ensures that the HACCP plan effectively prevents hazards and meets industry standards.

For example, a restaurant might conduct regular audits to ensure its HACCP plan is followed correctly. Verification helps to reinforce the commitment to food safety and can provide valuable insights for improvement, keeping businesses compliant with safety regulations.

7. Document and Record-Keeping

Documentation and record-keeping are the final principles of HACCP. Accurate records show that the HACCP plan is implemented correctly and that any corrective actions are taken when needed.

This documentation can be crucial during audits or regulatory inspections, providing proof of compliance.

A food processing company, for instance, may document cooking times, temperatures, and cleaning schedules to show that they’re following safety guidelines. Good record-keeping supports transparency and clearly records the company’s commitment to food safety.

Benefits of Implementing HACCP

There are several advantages to adopting HACCP for food businesses, from preventing foodborne illness to meeting regulatory requirements.

1. Improved Food Safety

The main goal of HACCP is to improve food safety by identifying and controlling potential hazards before they reach the consumer.

When focusing on prevention, HACCP reduces the risk of foodborne illness outbreaks and contamination. This proactive approach ensures that every step of food production is carefully managed to maintain high safety standards.

2. Enhanced Consumer Confidence

Implementing HACCP builds trust with consumers. Customers are becoming more informed about food safety and prefer businesses to prioritize safe practices.

Knowing that a business follows HACCP can reassure customers that they are buying from a reputable source. Businesses that show a commitment to food safety can build long-term customer loyalty and confidence.

3. Regulatory Compliance

In many regions, HACCP is required by law as part of food regulatory compliance. When adopting HACCP, businesses can ensure they meet local and international safety standards, avoiding fines or legal issues.

Compliance with food regulatory compliance also demonstrates a commitment to safety, aligning with industry standards like those outlined in the SFA food regulation.

4. Cost Savings

While setting up HACCP involves an initial investment, it can save costs in the long run. When preventing contamination and reducing waste, businesses avoid costly recalls, legal claims, and damaging their reputation.

HACCP’s efficiency in production processes can also lead to additional savings by optimizing resources and minimizing waste.

HACCP in the Food Industry: Real-World Applications

HACCP is widely used across the food industry, from large-scale food manufacturers to small restaurants. Here are some examples of how HACCP is applied:

- Food Manufacturing: Many factories use HACCP to ensure that each step in production, from receiving raw ingredients to packaging, meets strict safety standards. For more on this process, see food processing. For instance, F&N Foods in Singapore applies HACCP to closely monitor pasteurization in their dairy products, ensuring all raw milk reaches safe temperatures to eliminate harmful bacteria.

- Food Service: Restaurants and catering companies apply HACCP to manage risks from preparation to serving. This is crucial in ensuring meals are safe for customers. In Singapore, Jumbo Seafood follows HACCP by strictly controlling storage temperatures for fish and shellfish to prevent bacterial growth, ensuring safe and high-quality seafood for their patrons.

- Retail Food Establishments: Grocery stores and retail outlets use HACCP to manage food handling and storage conditions, ensuring the safety of fresh and prepared foods. For example, NTUC FairPrice in Singapore enforces HACCP by regularly monitoring temperatures at their deli counters, maintaining freshness and safety for ready-to-eat items.

Challenges and Best Practices for HACCP Implementation

Implementing HACCP can significantly improve food safety but presents particular challenges.

Food businesses can address these obstacles by following best practices and making HACCP implementation smoother and more effective. Here’s a closer look at common challenges and the best ways to overcome them.

1. Training and Education

One of the biggest challenges in implementing HACCP is ensuring that all employees, from managers to food handlers, thoroughly understand and apply HACCP principles.

Since HACCP involves multiple steps, each requiring specific actions and careful monitoring, employees must be adequately trained. Lack of knowledge or misunderstandings can lead to mistakes, increasing the risk of contamination and affecting the entire food safety system.

Solution

To address this, businesses should prioritize regular training and education. Training should cover the basics of HACCP, such as identifying hazards, monitoring critical control points (CCPs), and taking corrective actions when needed.

This training should be ongoing to account for staff turnover and updates in food safety standards.

For example, many businesses in Singapore provide annual or biannual HACCP training to ensure that employees are up-to-date with the latest food safety practices and changes in food regulatory compliance, as seen in SFA food regulation.

Additionally, offering hands-on training sessions or workshops can reinforce the importance of HACCP, helping employees see how each principle applies to their daily tasks.

Training should also emphasize each employee’s role in maintaining a safe production environment. When staff understand that their actions directly impact food safety, they’re more likely to take their responsibilities seriously.

2. Documentation and Record-Keeping

Accurate documentation and record-keeping are fundamental to a successful HACCP system, but they can be challenging to maintain consistently. The HACCP process involves documenting each step, from hazard identification to monitoring CCPs and recording corrective actions.

Proper documentation supports food regulatory compliance and ensures F&B transparency, allowing businesses to track their food safety measures over time. It also lays the groundwork for conducting a thorough food safety audit, helping identify gaps and ensure that corrective actions are aligned with regulatory standards.

Solution

One way to simplify record-keeping is using digital tools and software designed for HACCP management. Digital records allow for more accessible organization, faster access, and simplified reporting, reducing the risk of human error often associated with manual documentation.

For instance, many food manufacturers use digital platforms to log cooking temperatures, cleaning schedules, and other CCP monitoring data, making it easier to retrieve and review information as needed.

Implementing a system of regular checks and audits can also improve documentation practices. When conducting internal audits, businesses can identify gaps or inconsistencies in record-keeping and make improvements before these issues become serious.

3. Continuous Improvement

A HACCP system is not a “set it and forget it” solution; it requires ongoing improvement to remain effective.

Food safety standards, potential hazards, and regulatory requirements can change over time, making it necessary for businesses to regularly review and update their HACCP plan. A static HACCP plan may leave a business vulnerable to new risks or fail to meet updated safety regulations.

Solution

To support continuous improvement, businesses should schedule periodic reviews of their HACCP plan. This can involve reassessing hazards, re-evaluating CCPs, and ensuring that critical limits remain relevant.

Regular testing and verification procedures are also crucial for continuous improvement. When verifying that the HACCP system is working as intended, businesses can adjust based on accurate data, ensuring that potential gaps are addressed promptly.

Engaging employees in the improvement process can be highly beneficial. Employees who work directly with food production often have valuable insights into potential hazards or inefficiencies.

By involving them in reviews and updates, businesses can create a more practical and effective HACCP system.

Conclusion

So, what is HACCP, and why is it important? HACCP is vital for ensuring food safety in the food industry, protecting consumers from foodborne illness, and supporting businesses in maintaining high standards.

From identifying hazards to documenting every step, HACCP helps businesses create safer products and comply with food regulatory compliance standards.

Adopting HACCP allows businesses to build consumer trust, prevent contamination, and meet industry requirements, contributing to a safer food system for everyone.